Hazardous Material Storage Standards

Safely storing hazardous materials is essential to any safety program and to prevent injuries, fires, and unhealthful conditions.

Through its Hazard Communication Standard, the Occupational Safety and Health Administration (OSHA) requires employers inform workers about the hazards of chemicals they come in contact with through Safety Data Sheets (SDS) and appropriate labels.

Types of Common Hazardous Chemicals

Some common cleaning chemicals can be hazardous, causing various health issues ranging from skin rashes and burns to coughing and asthma.

Consult SDS to determine if a cleaning chemical is hazardous, if it needs proper storage, and how to store it.

Flammable liquids are defined and categorized into four categories according to OSHA Standard 1910.106(a)(19):

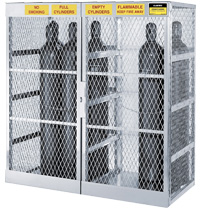

Gases such as atmospheric gases, fuels, refrigerants, and poisons, can be compressed into gas cylinders and used for various purposes.

There are a number of hazards to be aware of when gases are compressed into gas cylinders. Some hazards include:

- Oxygen displacement

- Explosions

- Toxic effects

- Physical hazards of ruptured cylinders

Gas Cylinder Inspection, Storage, and Handling

Proper cylinder inspection, storage, and handling will help reduce hazards associated with compressed gas cylinders.

OSHA standard 29 CFR 1910.101 establishes general requirements for compressed gases. The standard sets forth requirements for employers to visually inspect cylinders to ensure they are in a safe condition.

Gas cylinders should be properly secured with straps or chains connected to walls or other fixed surfaces to prevent falling, tipping, or rolling. Cylinders should be stored in a cool, dry, well-ventilated, fire-resistant area that meets all applicable federal, state, and local regulations.

Dropping or striking a cylinder may damage the gas cylinder valve, which could turn the gas cylinder into a dangerous torpedo with the potential to destroy property and/or cause injury.

Consult the appropriate SDS for detailed information on the chemical contained in the gas cylinder as well as handling and storage precautions.

Storing Chemicals Outdoors

If you store flammable or combustible chemicals outdoors at your worksite, your storage area must meet the National Fire Protection Agency's (NFPA) Code 30, Uniform Fire Code (UFC) Articles 79 and 80, or applicable local codes. Refer to these codes for specific details and check with your local fire authorities to determine if you must comply with additional local codes.

Code 30 also establishes what type of building construction is required based on the category of flammable liquids you are storing. Category 1, 2, or 3 liquids must be stored in a building made of noncombustible material, such as steel, or a fire-rated building.

Fire-rated buildings are divided into categories based on the fire resistance of the walls, roof, and openings (doors and vents).

Storage Cabinets

Flammable chemicals should be stored in a fire safety storage cabinet that will contain a fire should the chemicals combust.

OSHA establishes that storage cabinets must limit the internal temperature to not more than 325°F when subjected to a 10-minute fire test using the standard time-temperature curve as set forth in Standard Methods of Fire Tests of Building Construction and Materials, NFPA 251-1969.

OSHA states that not more than 60 gallons of Category 1, 2, or 3 flammable liquids, nor more than 120 gallons of Category 4 flammable liquids may be stored in a storage cabinet.

Note that not more than three storage cabinets may be located in a single fire area according to the National Fire Protection Agency's fire code 30 Section 4-3.1.

All cabinets should be labeled in conspicuous lettering, "Flammable–Keep Fire Away."

Review OSHA Standard 29 CFR 1926.152 for construction compliance requirements for metal and wooden cabinets.

Watch this video to learn more about self-closing and manual closing safety storage cabinets.

Storage Cabinet Doors

Storage cabinets are available with manual and self-closing doors.

Workers must remember to close manual doors to ensure fires are contained should one occur. Self-closing doors automatically shut and latch, which safeguards against workers accidentally forgetting to close the doors.

If there is a need to keep self-closing doors open, they can be held open with a fusible link device. Should a fire occur when the doors are left open, the fusible link device will melt at 165°F, allowing the door to shut automatically.

Some state fire codes may require self-closing doors. Check with your local fire authorities to verify if your state requires self-closing doors.

Safety Cans

OSHA's maximum allowable size of containers and portable tanks for flammable liquids can be found in the chart below.

| Container Type | Category 1 | Category 2 | Category 3 | Category 4 |

|---|---|---|---|---|

| Glass or approved plastic | 1 pint | 1 quart | 1 gallon | 1 gallon |

| Metal (Other than DOT drums) | 1 gallon | 5 gallons | 5 gallons | 5 gallons |

| Safety cans | 2 gallon | 5 gallons | 5 gallons | 5 gallons |

| Metal drums (DOT specification) | 60 gallon | 60 gallons | 60 gallons | 60 gallons |

| Approved portable tanks | 660 gallon | 660 gallons | 660 gallons | 660 gallons |

Setting up a color-coded system will make it easy to identify, organize, and separate the type of flammable liquids stored in your safety cans. A color-coded system will help workers safely store liquids, which shouldn't be near each other.

Chemical Compatibility

While it might seem convenient to store all chemicals in the same cabinet, keeping chemicals in close proximity of each other may pose a dangerous risk. Below is a partial list of chemicals that are incompatible and should not be mixed or stored together.

Chemical Compatibility Chart

| Chemical | Incompatible With |

|---|---|

| Acetic acid | Chromic acid, nitric acid, hydroxyl compounds, ethylene glycol, perchloric acid, peroxides, permanganates |

| Acetylene | Chlorine, bromine, copper, fluorine, silver, mercury |

| Acetone | Concentrated nitric and sulfuric acid mixtures |

| Alkali and alkaline earth metals (such as powdered aluminum or magnesium, calcium, lithium, sodium, potassium) | Water, carbon tetrachloride or other chlorinated hydrocarbons, carbon dioxide, halogens |

| Ammonia (anhydrous) | Mercury, chlorine, calcium hypochlorite, iodine, bromine, hydrofluoric acid (anhydrous) |

| Ammonium nitrate | Acids, powdered metals, flammable liquids, chlorates, nitrates, sulfur, finely divided organic or combustible materials |

| Aniline | Nitric acid, hydrogen peroxide |

| Arsenical materials | Any reducing agent |

| Azides | Acids |

| Bromine | See Chlorine |

| Calcium oxide | Water |

| Carbon (activated) | Calcium hypochlorite, all oxidizing agents |

| Carbon tetrachloride | Sodium |

| Chlorates | Ammonium salts, acids, powdered metals, sulfur, finely divided organic or combustible materials |

| Chromic acid and chromium trioxide | Acetic acid, naphthalene, camphor, glycerol, alcohol, flammable liquids in general |

| Chlorine | Ammonia, acetylene, butadiene, butane, methane, propane (or other petroleum gases), hydrogen, sodium carbide, benzene, finely divided metals, turpentine |

| Chlorine dioxide | Ammonia, methane, phosphine, hydrogen sulfide |

| Copper | Acetylene, hydrogen peroxide |

| Cumene hydroperoxide | Acids (organic or inorganic) |

| Cyanides | Acids |

| Flammable liquids | Ammonium nitrate, chromic acid, hydrogen peroxide, nitric acid, sodium peroxide, halogens |

| Fluorine | Everything |

| Hydrocarbons (such as butane, propane, benzene) | Fluorine, chlorine, bromine, chromic acid, sodium peroxide |

| Hydrocyanic acid | Nitric acid, alkali |

| Hydrofluoric acid (anhydrous) | Ammonia (aqueous or anhydrous) |

| Hydrogen peroxide | Copper, chromium, iron, most metals or their salts, alcohols, acetone, organic materials, aniline, nitromethane, combustible materials |

| Hydrogen sulfide | Fuming nitric acid, oxidizing gases |

| Hypochlorites | Acids, activated carbon |

| Iodine | Acetylene, ammonia (aqueous or anhydrous), hydrogen |

| Mercury | Acetylene, fulminic acid, ammonia |

| Nitrates | Sulfuric acid |

| Nitric acid (concentrated) | Acetic acid, aniline, chromic acid, hydrocyanic acid, hydrogen sulfide, flammable liquids, flammable gases, copper, brass, any heavy metals |

| Nitrites | Acids |

| Nitroparaffins | Inorganic bases, amines |

| Oxalic acid | Silver, mercury |

| Oxygen | Oils, grease, hydrogen, flammable liquids, solids or gases |

| Perchloric acid | Acetic anhydride, bismuth and its alloys, alcohol, paper, wood, grease, oils |

| Peroxide, organic | Acids (organic or mineral), avoid friction, store cold |

| Phosphorus (white) | Air, oxygen, alkalis, reducing agents |

| Potassium | Carbon tetrachloride, carbon dioxide, water |

| Potassium chlorate | Sulfuric and other acids |

| Potassium perchlorate (see also chlorates) | Sulfuric and other acids |

| Potassium permanganate | Glycerol, ethylene glycol, benzaldehyde, sulfuric acid |

| Selenides | Reducing agents |

| Silver | Acetylene, oxalic acid, tartartic acid, ammonium compounds, fulminic acid |

| Sodium | Carbon tetrachloride, carbon dioxide, water |

| Sodium nitrate | Ammonium nitrate and other ammonium salts |

| Sodium peroxide | Ethyl or methyl alcohol, glacial acetic acid, acetic anhydrite, benzaldehyde, carbon disulfide, glycerin, ethylene glycol, ethyl acetate, methyl acetate, furfural |

| Sulfides | Acids |

| Sulfuric acid | Potassium chlorate, potassium perchlorate, potassium permanganate (similar compounds of light metals, such as sodium, lithium) |

| Tellurides | Reducing agents |

Shop Safety Posters & Employee Safety Training Manuals

NOTE: This information is a summary interpretation and was prepared as general reference material only. This summary is not authoritative as laws can be amended over time. For specific compliance requirements and updates, please refer to the actual code language and the statute or legal counsel.