Respiratory Protection Standards

The Occupational Safety and Health Administration (OSHA) requires respiratory protection for workers who are exposed to harmful dust, fog, smoke, fumes, gases, vapors, sprays, or insufficient oxygen. Providing the right respirator not only complies with OSHA safety standards, it helps prevent serious illnesses like cancer and lung disease.

When to Use Respirators

Per OSHA requirements, respirators must be used to "protect employees from breathing contaminated and/or oxygen-deficient air when effective engineering controls are not feasible, or while they are being instituted." In short, when workplace practices cannot control or contain the airborne contaminants, respirators are the solution. Be aware that no respirator can 100% prevent contaminants from entering the wearer's breathing zone. It is vital that the right type of respirators are available for the right situation.

Approved Respirators

OSHA requires the use of NIOSH certified respirators.

National Institute for Occupational Safety and Health (NIOSH) certifies respirators, and classifies them with N, R, and P series. There are also three levels of filter efficiency: 95%, 99%, and 99.97%.The class of filter will be labeled on the filter, filter package, or respirator box. A respirator labeled N95 means you have an N series filter that is 95% efficient.

NIOSH explains the classifications this way:

The selection of N, R, and P series filters depends on the presence or absence of oil particles, as follows:

- If no oil particles are present in the work environment, use a filter of any series (i.e., N, R, or P series).

- If oil particles (e.g., lubricants, cutting fluids, glycerine, etc.) are present, use an R series or P series filter. Note: N series filters cannot be used if oil particles are present.

- If oil particles are present and the filter is to be used for more than one work shift, use only a P-series filter.

Note: To help you remember the filter series, use the following guide:

- N for Not resistant to oil

- R for Resistant to oil

- P for oil Proof

Selection of filter efficiency (i.e., 95%, 99%, or 99.97%) depends on how much filter leakage can be accepted. Higher filter efficiency means lower filter leakage.

Types of Respirators

Selecting the right type of respirator for the situation is vital. Respirators are available in half mask and full face coverage, and each style performs differently. The three ways respirators work:

- Filter out airborne particle

- Chemically purify the air

- Supply clean air from another source

Particulate Respirator/Air Purifying masks are for lower level hazards, and protect against dust, fumes, and mists. There are gauze particulate masks used for dust, and canister-type masks with replaceable filters.

Chemical Cartridge/Gas Masks feature a facemask, a cartridge, and straps. They filter gasses, vapors, and dangerous chemicals from the air as you breathe.

OSHA has a color-coded system to help identify the type of protection:

- White: acid gases

- White with a half-inch green stripe: hydrocyanic acid gases

- White with a half-inch yellow stripe: chlorine gas

- Black: organic vapors

- Green: against acid gas and ammonia gas

- Blue: carbon monoxide

- Yellow: acid gases and organic vapors

- Yellow with a half-inch blue stripe: hydrocyanic acid gas and chloropicrin vapor

- Brown: acid gases, organic vapors and ammonia gases

- Purple: (magenta): radioactive materials, except tritium and noble gases

- Purple: any particulate-P100 rating

- Orange: any particulate-rating of P95, P99, R95, R99, or R100

- Olive: chemical, biological, radiological, and nuclear gases and materials

- Teal: oil-free particulate-rating of N95, N99, or N100

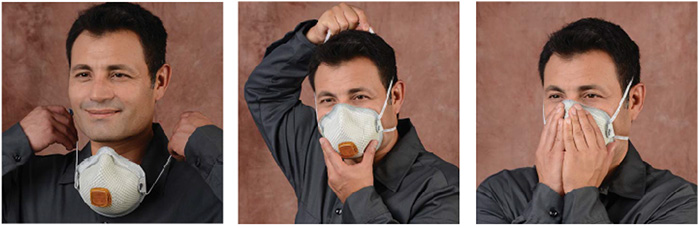

Training & Fit Tests

Not only are employers to provide proper respiratory protection, but fit tests and training are also required. OSHA requires training and fit tests prior to first use of respirators, and annually after that.

3M™ Fit Testing Materials can help you meet OSHA requirements. For more information on specific guidelines, please consult OSHA directly for fit testing and their FAQs regarding respiratory protection.

Consult OSHA directly specific guidelines for fit testing.

See OSHA's FAQs regarding respiratory protection.

Shop Respiratory Protection & Safety Equipment

NOTE: This information is a summary interpretation and was prepared as general reference material only. This summary is not authoritative as laws can be amended over time. For specific compliance requirements and updates, please refer to the actual code language and the statute or legal counsel.