Eye & Face Protection Requirements

Each year, thousands of people are blinded or suffer eye injuries while on the job. OSHA reports these injuries "cost more than $300 million per year in lost production time, medical expenses, and worker compensation." Even a small bit of dust or tiny particle in the eye can cause lifelong issues and medical expenses.

OSHA safety standards require employers to provide eye and face protection whenever necessary, and staff should be properly trained on how to use it.

When to Use Eye & Face Protection

OSHA standards require eye protection for anyone who is working or watching work involving "chemical, environmental, radiological, or mechanical irritants and hazards." The types of jobs that require eye and face protection include any work that could produce dusty conditions or flying particles such as slivers of wood, metal, plastic, plaster, etc.

Wear protective eyewear if you are watching or performing these kinds of tasks:

- Hammering, sanding, or grinding

- Using power tools, such as drills, nail guns, saws, or routers

- Working with any chemicals, even common cleaners like ammonia and bleach

- Landscaping with mowers, edgers, trimmers, or saws

- Working with cement, sealers, or drywall

- Welding

Types of Protection

Eyewear must fit properly and be designed to protect the eyes based on the activity being performed.

The American National Standards Institute (ANSI) has set criteria and performance standards for eye and face protective devices. ANSI/ISEA Z87.1-2010 encourages safety by focusing on the type of hazard. Employers and staff should evaluate workplace hazards and choose protection accordingly.

Types of hazards:

- Impact

- Optical radiation

- Splash

- Dust

Eye & Face Protector Selection Chart

Protective devices do not provide unlimited protection. This information is intended to help identify and select available eye and face protectors, their capabilities, and limitations the hazards listed. This guide is not intended to be the sole reference in selecting the proper eye and face protector.

Employers should match the hazard that workers need protection from with the right protection products.

Use ANSI/ISEA Protector Selection Chart to understand when you need spectacles, goggles, faceshields, and etc.

| Hazard | Protectors | Limitations | Marking 1 |

|---|---|---|---|

| IMPACT - Chipping, grinding, machining, masonry work, riveting, and sanding | |||

| Flying fragments, objects, large chips, particles, sand, dirt, etc. |

|

Caution should be exercised in the use of metal frame protective devices in electrical hazard areas. Metal frame protective devices could potentially cause electrical shock and electrical burn through contact with, or thermal burns from exposure to the hazards of electrical energy, which include radiation from accidental arcs. Atmospheric conditions and the restricted ventilation of a protector can cause lenses to fog. Frequent cleaning may be required. |

|

| HEAT - Furnace operations - pouring, casting, hot dipping, gas cutting, and welding | |||

| Hot sparks |

|

Spectacles, cup and cover type goggles do not provide unlimited facial protection. Operations involving heat may also involve optical radiation. Protection from both hazards shall be provided. |

|

| Splash from molten metal |

|

||

| High temperature exposure |

|

||

| CHEMICAL - Acid and chemical handling, degreasing, and plating | |||

| Splash and irritating mists |

|

Atmospheric conditions and the restricted ventilation of a protector can cause lenses to fog. Frequent cleaning may be required. | Splash / droplet: D3 |

| DUST - Woodworking, buffing, and general dusty conditions | |||

| Nuisance dust |

|

Atmospheric conditions and the restricted ventilation of a protector can cause lenses to fog. Frequent cleaning may be required. | Dust: D4 Fine dust: D5 |

| OPTICAL RADIATION | |||

| Nuisance dust |

TYPICAL FILTER LENS SHADE: 10-14 |

Protection from optical radiation is directly related to filter lens density. Select the darkest shade that allows adequate task performance. Note: Filter lenses shall meet the requirements for shade designations in table 6 of ANSI/ISEA Z87.1-2010. |

Welding: W shade number UV: U scale number Glare: L scale number IR: R scale number Variable tint: V Special purpose: S |

|

Welding: Gas Viewing gas-fired furnaces and boilers |

TYPICAL FILTER LENS SHADE: 4-8 |

||

| Cutting |

TYPICAL FILTER LENS SHADE: 3-6 |

||

| Torch brazing |

TYPICAL FILTER LENS SHADE: 3-4 |

||

| Torch soldering |

TYPICAL FILTER LENS SHADE: 1.5-3 |

Shade or special purpose lenses, as suitable. Note: Refer to definition of special purpose lenses in ANSI/ISEA Z87.1-2010. |

|

| Glare |

|

||

1. Refer to ANSI/ISEA Z87.1-2010 table 4a for complete marking requirements.

Edge Safety-Rated Eyewear - HD Supply Facilities Maintenance

Coatings & Tints

As you consider safety glasses, goggles, and faceshields, you want to be sure you have the appropriate coating and/or tint for the job.

Anti-Fog Coatings

Fog happens in almost every kind of job. Fogging happens if you are in hot or humid conditions, or if you move from cool to warm areas as you work. Even rising body heat can cause safety lenses to fog.

Stopping to wipe, clear, or remove safety glasses puts workers at risk and can affect productivity. To avoid this, choose high-performance anti-fog safety glasses or anti-fog goggles.

Anti-Scratch Coatings

Scratches on safety goggles, safely glasses, and face shields can affect employee safety and productivity. If their field of vision is obscured, workers do not have a clear view of their work and possible hazards. Select scratch-resistant safety glasses and safety goggles whenever possible. They will help improve worker safety and performance, and they will last longer.

Tints

Safety lens tints should be specific to the type of work and light exposure. Most commonly, tints are required for workers who are welding, brazing, or face other intense light.

The ANSI/ISEA Z87.1-2010 standard recommends tinted lenses for work in direct sunlight, such as landscaping or grounds maintenance. Clear lenses are recommended for standard inside work with normal lighting. Safety glasses with clear lenses or specialized indoor tints are ideal. If tinted lenses are required for indoor or outdoor use, they should be the appropriate color and darkness to protect against the identified hazard.

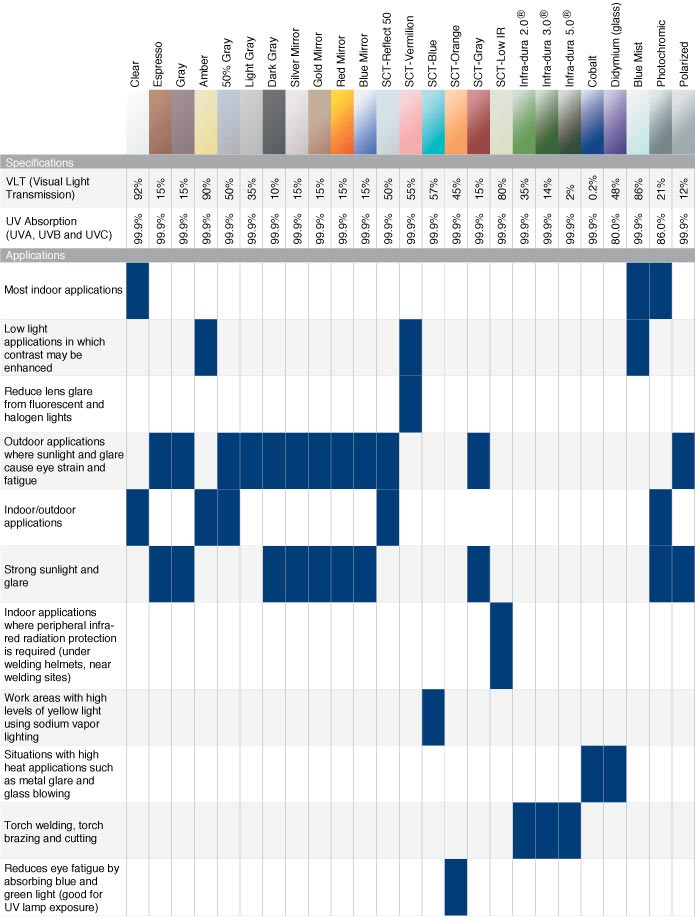

Uvex has created a useful reference chart to help you identify the best lens tints for specific conditions:

Tint Protection Chart

Shop Eye & Face Protection

NOTE: This information is a summary interpretation and was prepared as general reference material only. This summary is not authoritative as laws can be amended over time. For specific compliance requirements and updates, please refer to the actual code language and the statute or legal counsel.